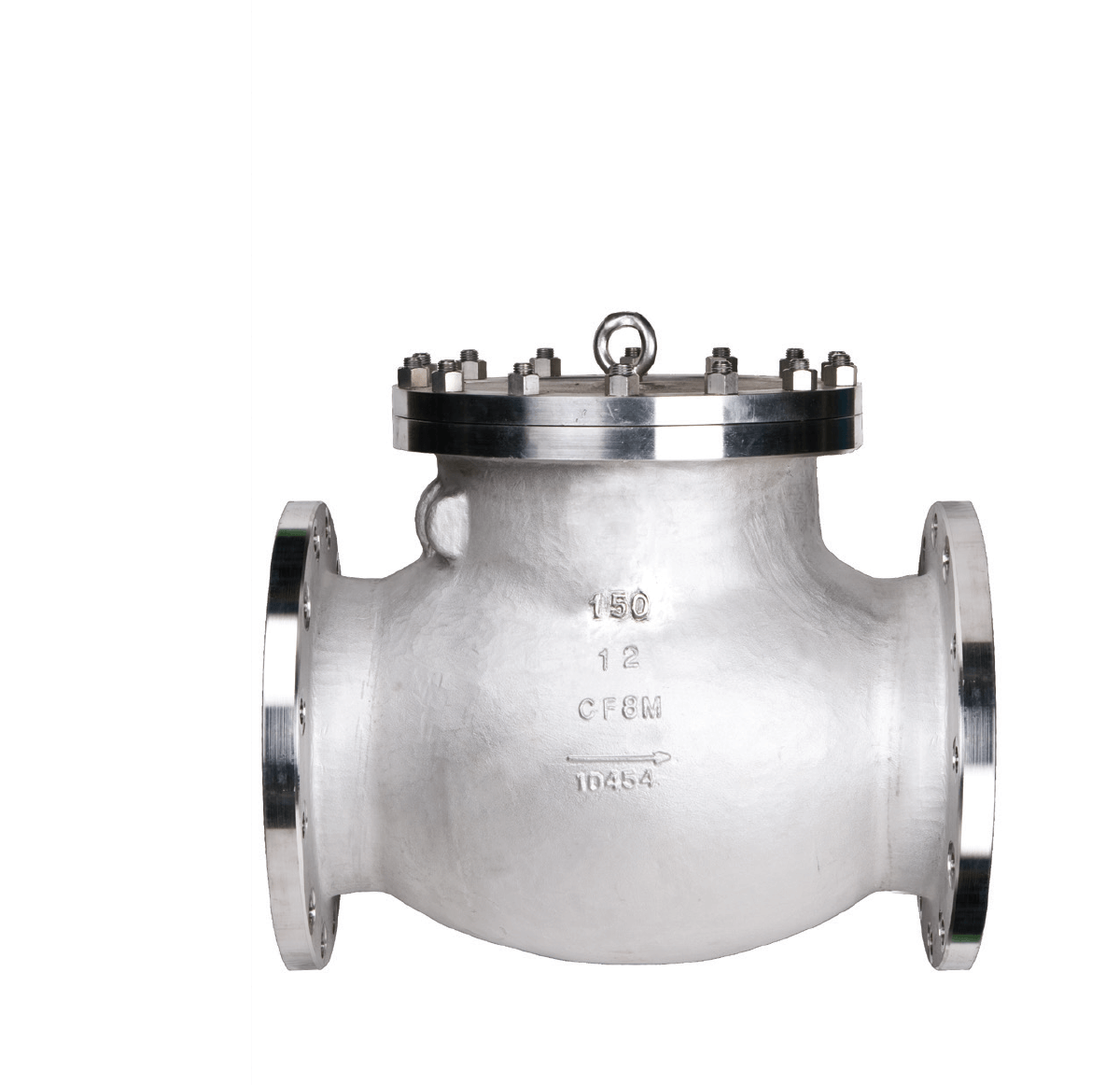

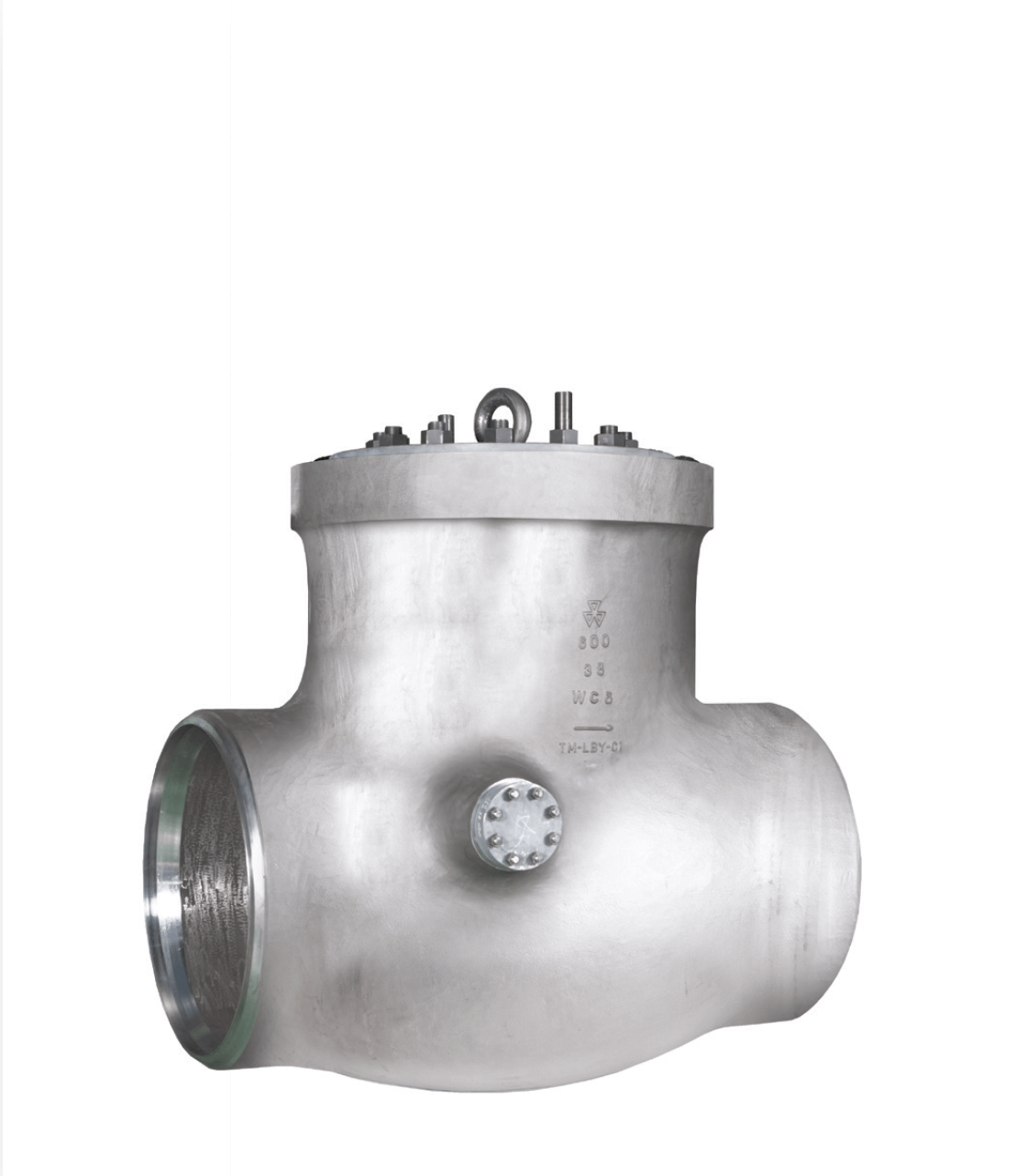

Swing Check Valve

- Opened automatically at the forward flow and closed at the reverse flow. The disk is held by an arm which rotates on a pin contained in the seat upon exertion of fluid pressure on the reversal pressure and the weight of the disk close the disk against the seat, stopping back flow.

- Can be installed horizontal pipe line, and can also be installed the vertical position (upward flow only through valve).

- This design keeps minimize the stress, turbulence and resistance to flow.

- This type of valve has an advantage light weight and easy maintenance.

- This type valve is best suited for moderate velocity applications.

- Body penetration is sealed with blind flange and seal ring (Inner shaft type is available without body penetration).

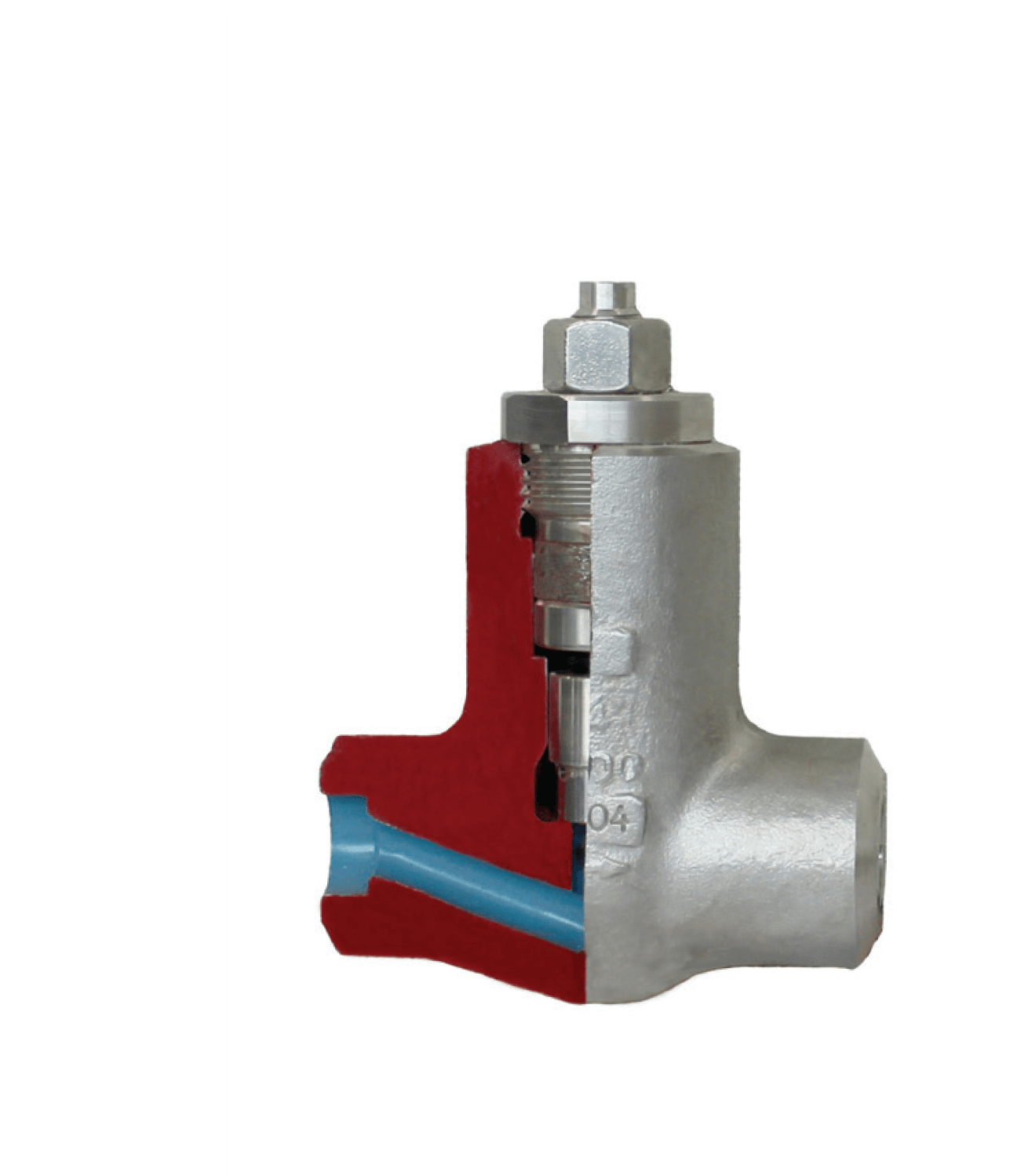

Lift Check Valve

- Lift check valves are designed so that it is opened automatically at the forward flow and closed at the reverse flow.

- This design keeps minimize the stress, turbulence and resistance to flow.

- WHERE RAPID FLOW REVERSAL MAY OCCUR- lift check valves are excellent for services where rapid flow reversal may occur. The travel of a lift check valves is the shortest of all the check valves thus travel to and from the seat is faster. In addition, the lift check is inherently rugged by design having no hinge pins, bushings, or bolted connections which are subject to impact loads when the valve seats.

- Lift check valves are installed horizontal pipe line, and can also be installed the vertical position.

- EXCELLENT FOR LOW OR PULSATING FLOWS- as described above, the lift check has the shortest stroke and fewest number or parts subject to impact loads and wear, this makes the lift check an excellent selection for services where low or pulsating flows are expected. for some services a lift check with a special lightweight disk should be considered. The lightweight disk minimizes pressure drop at low flow conditions and extremely low flow rates, eliminates the possibility of “chugging” or “simmering” (repeated seating and unseating).

- WHERE TIGHT SEALING IS REQUIRED- lift check valves have moderate sealing capability and can provide tight shut off if the differential pressure across the disk is relatively large. For that shutoff at lower differential pressure (less than approximately 100 psi) an elastomeric dual seat is recommended.